Welcome to Power High Engineers Pvt. Ltd.

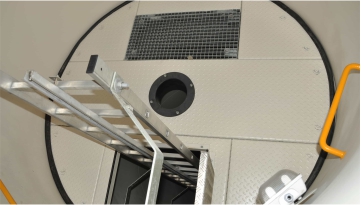

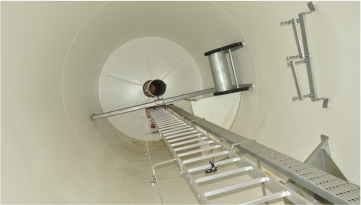

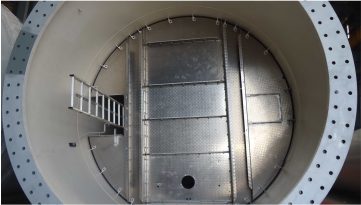

We, “Power High Engineers Private Limited,” established in the year 2003 at Ahemdabad (Gujarat, India), are a prominent Manufacturer and Supplier of a qualitative assortment of Internal Assembly Parts for Wind Mill Tower. The offered product range is designed & manufactured using superior quality raw material that we procure from the reliable vendors of the industry in compliance with international quality standards. Also, our professionals use advanced machinery and innovative technology in manufacturing the products. These products are highly appreciated among clients for their sturdy construction, robust design, high durability and long service life. We offer our product range in various specifications and can be customized as per the specific requirements of our clients at reasonable price range. Additionally, we offer highly effectual and reliable services for Plasma Cutting Service, Plasma Cutting Job Work, Heavy Structural Fabrication, Heavy Structural Job Work and Steel Structural Fabrication.

Wind Mill

We are successfully positioned ourselves the well known company for presenting a broad range of Wind Mills. Our offered wind mill is examined by our competent experts on various terms of quality in order to meet the dappled necessities of clients.

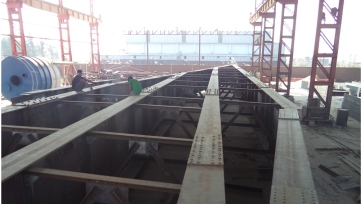

Heavy Structural Fabrication

We are a unique entity in the industry, actively committed to offering an optimum quality Heavy Fabrication Services. The provided services are executed by our professionals using optimum quality tools and latest technology.

CNC Plasma Cutting Job Work

We offer a wide range of CNC Plasma Cutting Job Works. Available in different sizes and specifications. The CNC Plasma Cutting Services we offer to the customers have been priced at very reasonable rates in the market

Know About POWER HIGH

Capacity

The unit is capable of making 800 sets of Internals and assembly for any tower model per annum.

Experience

3300 sets of tower internals supplied to SUZLON / Gamesa / GE which include over 275 sets of WTG TT Internals made for their Export towers (exported to USA / EUROPE / SRI LANKA).

Added features

We are the first and only Wind Tower Internal manufacturer in INDIA who has attained ISO 9001-2015, ISO 14001- 2015 and BS OHSAS 18001-2007 - INTEGRATED MANAGEMENT SYSTEM certificate for the product and service.

Way Forward

We have plans to expand our horizon of business by entering in the area of Solar energy with supply of Mounting Structure and components for Solar panel as well as Export of Internals & Assembly Parts for Wind mill towers.

LOOKING AN ADEQUATE SOLUTION FOR YOUR COMPANY?

REQUEST A QUOTEFrom Idea To Realization

We have Advance Cutting facility of CNC PLASMA Cutting machine – 03Nos. with Dual torch station (Cutting table – 15.0m L x 4.5m W) and Hydraulic shear machines. Additionally we also have Plasma arc cutting system equipped with PUG machine.

Numerous NC Press Brake with NC back gauge of required size and capacity carries out most critical process of Bending for efficient operation and precision dimensional out put with excellence qualitatively and quantitatively.

Hydraulic presses are available of 500 MT & 300MT capacities for the most significant activity of doorframe making for wind tower.

We have a sizable strength of Experienced / Qualified / Trained welding operators to achieve excellence in all type of welding process with equipments like CO2 MIG Welding, welding Rectifier Machine and TIG/MIG/ARC TPS – 2700 (welding system especially for aluminum welding) available large in numbers.

Having advance facility for machining like Planning, Shaping & Milling. We also have LMW make CNC Turning M/C.

We are prepared with all the facilities for surface preparation which include Painting/Spray Galvanizing / hot dip galvanizing process and various type of protective coating.

In addition to all above, we also have following support services.

• Development of drawings on auto cad to support design.

• Documentation system in terms of Quality/EMS/OHSAS

• Proto type development for R&D.

Our Clients